Maybe your dad used a Pyrex measuring cup whenever he made pancakes, or your roommate always baked her famous lasagna in a rectangular Pyrex pan, or your grandmother had a set of the brightly colored Pyrex mixing bowls on her kitchen counter. That’s why, for most of us, it’s impossible to recall the first time we encountered Pyrex: Almost from its debut in 1915 as the first glassware for cooking, Pyrex has been a ubiquitous part of the American kitchen. To celebrate the Pyrex centennial, the Corning Museum of Glass has organized an exhibition detailing the brand’s historic legacy called “America’s Favorite Dish: Celebrating a Century of Pyrex,” up through March of 2016.

“Pyrex has affected our national memory.”

Pyrex’s utilitarian, streamlined designs—and even its technical-sounding name—implied that cooking was a science to be mastered using mathematical perfection. And in fact, the temperature-resistant glassware has its roots in the groundbreaking laboratories at the Corning Glass Works, a company that initially manufactured glass for industrial purposes. Indeed, the kitchenware line we take for granted once provided the material for the world’s largest telescopic mirror.

Top: A two-quart covered casserole dish produced by Pyrex in 1960. Above: Left, a set of mixing bowls in the Dots pattern, circa 1970. Right, a Pyrex liquid measuring cup from 1953. Courtesy the Corning Museum of Glass.

Founded in 1851 near Boston as the Bay State Glass Company, the business moved to Brooklyn briefly before finding a permanent home in Corning, New York, in 1868. At that time, the company was focused on technical products, particularly those needed in the booming railroad industry, from glass battery jars to lenses for train signals.

However, in the late 19th century, glass globes used for railroad signal lanterns often shattered when the heat of a light came into contact with snow, rain, or even just the cold night air—a phenomenon known as thermal shock. “Obviously, if a signal lens goes out that creates a dangerous situation, so railway representatives came to Corning Glass Works and asked them to help solve the problem,” says Regan Brumagen, one of the curators of the Corning Museum’s Pyrex exhibition. (Though founded by the Corning Glass Works, the museum is a structurally separate nonprofit devoted to preserving and expanding the world’s understanding of all glass.)

An engraving from the 1870s showing the Corning Glass Works cutting department. Courtesy the Corning Museum of Glass.

“When glass, or any solid, is heated up, it expands; conversely, when it is cooled, it contracts,” explains Glen Cook, the chief scientist at the Corning Museum of Glass. “The amount of growth and shrinkage is too small to be seen, but from the perspective of the atoms in the glass, it is enough that if one part of the object is getting hotter or colder much faster than another part, the stress created between those two parts can literally rip the glass apart—it breaks or shatters.”

In the early 20th century, Corning scientist Eugene Sullivan worked to develop a unique glass formula that could withstand this stress, using his previous experience working with Otto Schott, inventor of the first glass recipe incorporating boron. “Boron atoms arrange themselves in the glassy network of atoms in such a way that they make the overall piece of glass change size less, almost two-thirds less, than standard glass lacking boron,” says Cook. In 1909, Corning began marketing its borosilicate glass products as Nonex or CNX (Corning Non-Expansion).

During the early 20th century, glass wasn’t used for cooking because it couldn’t withstand extreme temperature fluctuations. Instead, cooks relied on earthenware, cast iron, or tin vessels that could be heated easily. However, as the company began looking for novel ways to use its durable glass, its staff was steered toward the development of consumer kitchen products by the wife of one Corning physicist.

“The story is that Dr. Jesse Littleton was discussing it over dinner with a colleague and with his wife, Bessie, who suggested that maybe this glass could be used for bakeware,” says Brumagen. “One of Bessie’s earthenware casserole dishes had just shattered in the oven, and she was annoyed because it was only the second time she had used it. So Dr. Littleton brought a sawed-off piece of a Nonex battery jar and Bessie made sponge cake in it. She ended up making custards in lamp chimneys and lots of other things to test them out for the company.”

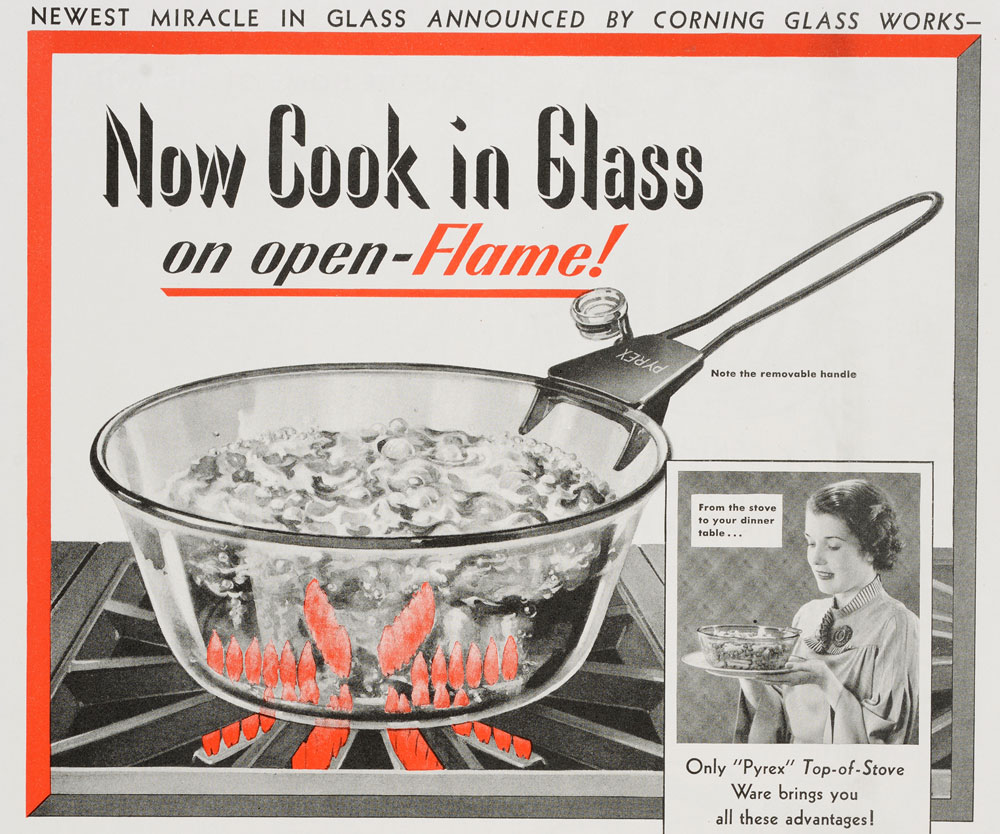

Bessie’s experiments revealed that the borosilicate glassware heated quickly and evenly, its transparency made it easier to monitor the progress of a dish while baking, and it was easy to clean. The company soon created a new division focused on consumer products and launched its Pyrex line with 12 clear ovenware dishes in 1915. “It was a challenge to convince people to use Pyrex,” says Brumagen. “All the early ads say things like, ‘Yes, you can cook in it!’ or ‘Bake in glass!’ It was just a foreign concept to consumers, so Corning had to do some persuading.” In its early Pyrex marketing, the company purposefully used the jarring imagery of open flames visible through the clear glass to convey the potential of its new products.

An ad for Pyrex “Top-of-Stove” ware from 1936 shows the flames through the pan’s clear glass. Courtesy the Corning Museum of Glass.

The brand’s scientific-sounding name was chosen to fit with the company’s industrial lines, as several already ended in “ex.” “When they developed the Pyrex formula, the first dish they made was a pie plate,” says Brumagen. “I think it was Dr. Sullivan who wanted to call it ‘Pierite’ but was eventually overruled, and it became Pyrex since that fit with the family of products they already had—and, of course, ‘pyr’ is the prefix meaning ‘fire.’ The first ads had a little tag line underneath in quotations that said ‘fire glass,’ but they dropped that pretty fast.”

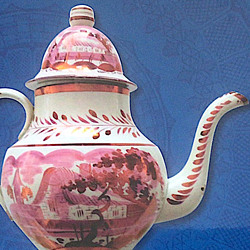

An engraved Pyrex tray featuring the Corning Glass Works factory, circa 1920s. Courtesy the Corning Museum of Glass.

The Pyrex name got a major publicity boost beginning in 1929, when astronomer George Ellery Hale commissioned Corning to produce a 200-inch glass disk (nearly 17 feet) for a huge new telescope in California—twice the diameter of the largest existing telescopic mirror at the time. Manufacturing such disks required specialized materials and extreme precision, for if the glass expanded and contracted unevenly, its imagery would forever be distorted. Corning physicist Dr. George V. McCauley designed a gigantic disk for Hale using the Pyrex borosilicate formula and incorporating a complex honeycomb surface pattern to lighten the object’s weight.

Though an initial attempt at the 200-inch disk failed, McCauley’s team successfully completed the task in December of 1934, after which the disk was gradually cooled for 10 months through a process known as annealing. Thousands of people flocked to railway lines as the giant Pyrex shipping crate carrying the glass made its way from New York to California, where it would be carefully ground, polished, and finally installed in 1948.

Left, the telescope disk’s shipping crate is prepared for transport in 1935. Right, the disk’s diameter is measured after being cast. Courtesy the Corning Museum of Glass.

As the Pyrex team attempted to battle a slump in sales during the 1920s, Corning native Lucy Maltby was spending her graduate studies investigating Pyrex and the ways it might be improved, finally convincing the company to hire her in 1929. “Maltby was part of this wave of home economists in the professional world—that was the new women’s career at that point,” says Brumagen. Part of Maltby’s role was to be the voice of the consumer. “She was the one to say, ‘Hey, this cake dish is really fantastic but it has no handles, so every time I pick it up with cake batter in it, my thumb goes right in the batter,'” Brumagen explains. Maltby was the one to point out that their pans were too big, meaning you couldn’t fit two of them in the oven at the same time, and something like a double-layer cake would take twice as long.

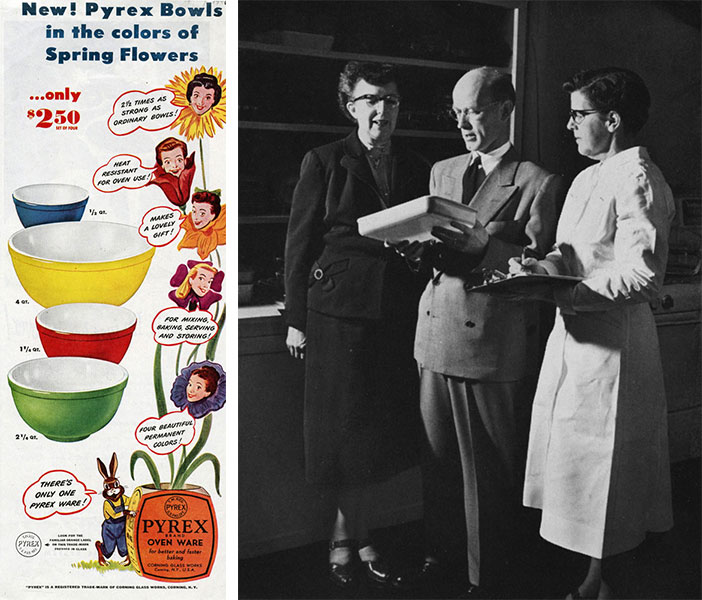

The Corning staff was impressed with Maltby’s research, and she launched Corning’s new test kitchen in 1931. Brumagen says Maltby immediately had a strong influence on Pyrex design and expanded the company’s reach into the home-consumer market. “She had a whole staff of people, including field agents who would meet with department-store managers, give demonstrations, and talk to customers directly. Matlby’s staff read thousands of letters from consumers, making notes and reporting back to her about complaints or things that they were doing right.” Maltby ensured that the all-male sales crew underwent a thorough training with Pyrex products in her test kitchen, as well as typical household chores.

Left, an ad for Pyrex mixing bowls from 1946. Right, Dr. Lucy Maltby, Charles Oliver, and June Packard discuss a new product line in 1954. Courtesy the Corning Museum of Glass.

Although Corning still made Pyrex products for laboratory use, its kitchenware became the biggest seller. Corning’s many innovations helped the business to quickly respond to American cooking trends, such as the popularity of home coffee brewers, shrinking oven sizes, or the spread of standardized baking mixes. “Pyrex pans originally had all these different sizes, and some were just one eighth of an inch bigger than others,” says Brumagen. “Maltby saw that this was too confusing, and wanted to simplify the line. She took a special interest in creating certain standards and making them suitable for kitchen use.” While working at Corning, Maltby also published cookbooks and completed her doctorate.

At a time when it was uncommon for women to have professional careers, Corning relied on its many female employees to create products that women would actually want to use. “You had this dichotomy between the image of the homemaker women they were selling to in the advertisements and this whole army of women who were involved in the process behind-the-scenes, from design to quality-control inspections,” says Brumagen.

Innovations in manufacturing were also making Pyrex a household name. Like the Palomar telescope disk, the earliest Pyrex cookware was made by hand, which limited its output. However, in the 1930s, advances made by engineers like Corning’s William Woods allowed Pyrex to be mass-produced using machine-pressed glass molds.

Left, glass cookware was advertised as a useful material to conserve metal during World War II. Right, Silver Streak electric irons were made from Pyrex glass in 1946. Courtesy the Corning Museum of Glass.

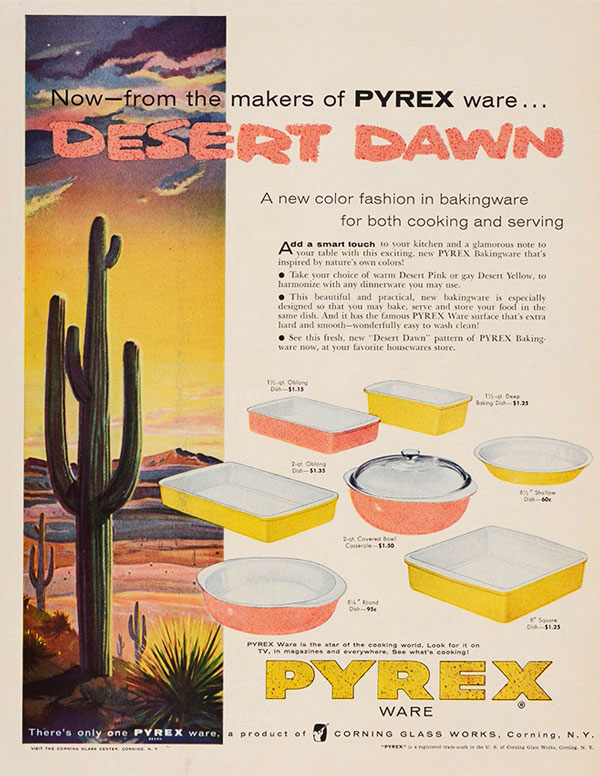

In 1942, the Museum of Modern Art praised the functionality of Pyrex designs by featuring several products in its exhibition “Useful Objects in Wartime under $10.” Around the same time, the company was developing a line of tough white dishes for military mess halls made from tempered soda-lime instead of borosilicate, making them less heat-resistant but also less likely to shatter when dropped. After World War II, this military glassware evolved into the brand’s popular Opalware line of kitchenware. The white glassware’s decorative appeal took a backseat until the end of the war, when Corning’s consumer division realized that Americans wanted more colorful objects in their homes.

A advertisement for the Pyrex Desert Dawn color scheme from 1955. Courtesy the Corning Museum of Glass.

“They really had this craving for something new,” says Brumagen, “something colorful and bright and cheerful, and you saw the introduction of primary colors. I imagine it had something to do with the end of the war and a desire to live it up a little more.” In the late 1940s, competitor Anchor Hocking‘s Fire-King label also took off, as its temperature-resistant dishes made in classic Anchorwhite and green Jade-ite materials were adopted by restaurants, schools, and military bases.

From that point on, Pyrex needed distinctive decoration and was designed with an increasing variety of colorful shades and patterns, usually painted onto white Opalware glass. From the ever popular primary-color mixing bowls to dishes in turquoise, pink, and avocado-green tones, Pyrex fit perfectly with the Mid-Century Modern aesthetic.

While some patterns were quickly dropped due to slow sales, others, like the Snowflake, Gooseberry, Dots, and Daisy designs, were produced for decades. Eventually, the brand also catered to the demands of home microwaves with glassware and recipes geared toward the time-saving device. In addition to its familiar cooking products, over the years the Pyrex label also encompassed household objects like baby bottles, thimbles, and electric irons, as well as its line of laboratory glassware, which included beakers and test tubes. Pyrex remained the company’s top-selling brand until it was overtaken in the 1970s by Corningware, a line made from a combination glass-ceramic formula produced since the late ’50s.

Today, Pyrex is manufactured by World Kitchen, which licensed the brand from Corning beginning in 1998, thus giving future generations the chance to grow up with Pyrex, too. “I’m not a collector, although I’ve always had a 13- by 9-inch Pyrex baking pan,” says Brumagen. “That was one of the things I got when I moved into my first apartment. I had to have that and a Pyrex measuring cup because my mom and my grandmother both had them, so I grew up baking with those. We hear things like that from people all the time, ‘Oh, my gosh, we used to have a turkey roasted in that dish.’ Pyrex definitely has a resonance with people—it’s affected our national memory.”

Mr. Chemex: The Eccentric Inventor Who Reimagined the Perfect Cup of Coffee

Mr. Chemex: The Eccentric Inventor Who Reimagined the Perfect Cup of Coffee

Easy-Bake Evolution: 50 Years of Cakes, Cookies, and Gender Politics

Easy-Bake Evolution: 50 Years of Cakes, Cookies, and Gender Politics Mr. Chemex: The Eccentric Inventor Who Reimagined the Perfect Cup of Coffee

Mr. Chemex: The Eccentric Inventor Who Reimagined the Perfect Cup of Coffee Making, and Eating, the 1950s' Most Nauseating Jell-O Soaked Recipes

Making, and Eating, the 1950s' Most Nauseating Jell-O Soaked Recipes PyrexIn 1915, chemists at Corning Glass Works in Corning, New York, created a sp…

PyrexIn 1915, chemists at Corning Glass Works in Corning, New York, created a sp… KitchenCollectible kitchen items span a wide range of objects, from teakettles and…

KitchenCollectible kitchen items span a wide range of objects, from teakettles and… Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Lovely article! I love my Pyrex. I can always rely on it to be useful, easy, and pleasing to look at. And now I have warm fuzzies because women were the ones who drove the quality.

The only thing left of Pyrex is the name. They don’t make it from the same glass and it breaks and shatters easily. Too bad they decided to cheapen such a quality name this way.

Where can I buy a Pyrex pie plate in Paris?

Now that everyone is scared of using plastic (and rightly so) Pyrex could make a comeback. I would buy the collection if it were available.

I love Pyrex and I have been most impressed with the Corning Museum Library; they have been so helpful with my inquiries. I have had the pleasure of working with Ms. Brumagen several times – she is so knowledgeable and patient!

Be very wary of recently manufactured Pyrex ware. I have had two Pyrex pie plates that I bought in Bangkok from a reputable store few years ago literally explode in my microwave while I was warming up left overs. Both plates had been out of the fridge for 10 minutes. Both had been warned up for only two minutes. Very violent explosion. I am using Corning Ware now.

Why is there no mention of Pyrex scientific glassware for chem. labs.?

Remember several trips to the Museum in the early 1970’s. They had an actual periscope that you could use to peer out at downtown Corning. (as a Kid… that was AWESOME)

as a budding scientist (OK, I was 8-10ish the first time), I loved all of the demonstrations of the properties of glass (Things like a machine that was repeatedly flexing a sheet, a demonstration of light transmitting thru a curved bar of glass, and a glass hammer driving nails. That bar was something my Uncle had me pay attention to. Later, when Fiber Optics came out, I knew why.

All ours was white with blue flowers.

The last paragraph is very misleading. World Kitchen produces products under the Pyrex brand, but they are not borosilicate– in the most important sense they are not “Pyrex”.

While the brand’s reputation currently resonates, the current inferior product will disappoint.

@9. That was pyrocermanic. Little different beast than this…

The white dishes with the blue flower are Corningware. That’s a different product made with ceramic originally developed for missile nosecones.

I have my mother’s primary color dishes from the 50’s

Pay attention when you purchase Pyrex. Nowadays, Dow-Corning sells pyrex (with a small p), which is soda-ash formulated tempered glass. It is much less temperature resistant and prone to breaking than Pyrex (capital P) which was borosilicate tempered glass. What a tangled web we weave, when first we practice to deceive. (a maxim drafted before modern marketing, but strangely prescient).

The last memory I have of my Daddy before he passed away in 1978 is of he and I sitting together on the sofa eating soup beans and cornbread out of a big serving bowl that was white with blue dots! That bowl is sitting on a shelf right now. I will not use it for fear it may be broken.

Agreed about the mis-branding of contemporary “pyrex” cooking gear – do NOT expect the same thermal resistance from it. It can be dangerous.

One nit-pick – the statement “once provided the material for the world’s largest telescopic lens” should read the “world’s largest telescope MIRROR.” A lens transmits light – a mirror reflects it and the 200 inch Mount Palomar telescope uses a Pyrex disk coated with aluminum.

Note: CGW, now Corning Incorporated sold off Pyrex in the Mid-late 90’s to World Kitchen. The current pyrex has nothing to do with Dow Corning or owned by Dow Corning. You are mixing up Corning subsidiaries.

And agreed. The World Kitchen is indeed inferior, because it is a different formula.

Shop flea markets, Salvation Armies and garage sales for the old stuff. After 80 years, the old stuff still is superior to the new pyrex.

Our mother passed away this summer and I took possession of all her pictures and memory books. While reading her “1946 Wedding Book” I looked down the list of wedding presents and found “Pyrex mixing bowls”. I have her two small Pyrex mixing bowls, one has a blue exterior and one pinkish. I found this site looking to see when the colored mixing bowls were introduced. Fun to see that they were introduced in 1946, so they probably received these as a wedding gift. I use them all the time! Very excited. I wish I had the whole set!

I recently moved countries again, so had to stock a new kitchen. I purchased some nice blue stoneware Pyrex. And it was nice, but didn’t last. Both cracked….in half.

Fortunately all the lovely ‘vintage’ Pyrex is priced about the same as new breakable Pyrex. I had my pick of unbroken pieces. So happy with my ‘new’ set. It’s the Pyrex, I always trusted.

Like they say, “They don’t make ’em like they used to.” If you guys are looking for vintage Pyrex, check out Etsy. Lots of Pyrex on there. This was a great article. I enjoyed learning the history of Pyrex.

I thought everyone knew that Pyrex brand glassware was no longer made with borosilicate glass? At least, Consumer Reports covered this in 2010.

Pyrex brand glassware is still heat-resistant, but, apparently it’s far more susceptible to thermal shock than it once was. As in, when you take the Pyrex out of a conventional oven and the surface you put it down on is wet, bang! goes your Pyrex (and your dinner).

NOT the same Pyrex today, it seems. Use with caution if the following is correct.http://blogs.discovermagazine.com/80beats/2012/09/13/pyrex-glass-isnt-as-shatterproof-as-it-once-was-report-finds/#.Wy_uY4onbTc