We’ve all known people who only buy Hondas, others who swear by their Volvos, and those who proclaim their undying loyalty to Chevys or Fords. But for farmers, brand allegiance to a particular make of tractor is in their blood, which generally flows John Deere green or Farmall red. It’s an emotional tie to be sure, but also one based on any number of hard, measurable metrics. After all, when it comes to workhorse vehicles such as tractors, the dependability of the machine, or its lack, can make or break you.

“I don’t think the dot-com revolution would have happened without tractors.”

In fact, farm-equipment companies have a long tradition of earning their customers’ business, and affection, by demonstrating the tangible value of their machines. “More than a century ago,” says Lee Klancher, “manufacturers would hold reaping competitions. It was a major event in a community. All the farmers would come out to watch two new pieces of equipment harvest comparable sections of a field. Whoever did best got the sale.

“There was a lot of money at stake, so there were a lot of dirty tricks,” he adds, “like sabotaging a competitor’s machinery or prepping the field so your section went quicker. That kind of stuff went on because it was a big business—in the middle of the 1800s, 70 to 80 percent of the populace was farming. It’s not like the salesmen were fighting over a small corner of a tiny market.”

Above: The view from the cab of the Case IH Magnums of the late 1980s gave farmers unprecedented visibility and ergonomic access to the tractor’s numerous controls. Photo: Gregg Montgomery Collection. Top: Introduced in 1958, the Farmall 560 sported new, more powerful hydraulics. Collection: Jerry Mez. Photo: Lee Klancher.

Lee Klancher has been a student of this market since 1992, when he first started photographing and writing about Farmall and other International Harvester tractors, which by then were sold under the name Case IH. This fall, Klancher’s coffee-table tome (he’s the lead author) was published, devoted to the company’s output since 1958, the year the firm entered its turbulent, modern era. Titled “Red Tractors: 1958-2013,” the 384-page, six-plus-pound book is an imposing work, almost requiring a tractor to lift it.

For Klancher, the arc from International Harvester Company in 1902 to Case IH in 1985 is not just the story of a tractor company: It’s a window on how the modern industrialization of farming has transformed the United States. Tractors and the labor-saving farm implements they pull, from cultivators and seeders to reapers and balers, have changed the character of the country from coast to coast, thinning populations in rural regions while beefing them up in the cities and suburbs.

“The part about tractors that’s really interesting to me,” Klancher says, “is the role they played in our society, transforming it from primarily agrarian to urban. In the mid-19th century, most of the U.S. populace was farming. By 1993, the government actually stopped counting farmers as a unique population group. Today, the world we live is incredibly urban, the rural way of life is essentially gone. That’s an enormous shift, and tractors enabled it. Without the tractor, without the mechanization of the farm, a larger percentage of the population would still have to be out there farming. I don’t think the dot-com revolution would have happened without tractors,” he adds. “If you look at the Internet, that’s the product of an industrialized nation.”

The 1026 Wheatland was only made from 1970-1971; fewer than 2,000 were sold. Collection: Huber Brothers. Photo: Lee Klancher.

Of course, just like those farmers whose blood runs red or green depending on their brand allegiance, it’s also a personal story. “My rural roots run pretty deep,” Klancher says. “My dad grew up near the tiny town of Willard, Wisconsin, and my family has a cabin and land there. That township is still 97 percent Slovenian, and for many years the only functioning business was my cousin’s bar.

“My grandfather was a dairy farmer,” he continues, “and my dad bought our house off a farm. Another family bought the farm itself, so there was a working farm right next door to where I grew up. After initially going to college for engineering, I had set out to be a science journalist when a publisher approached me to photograph a book about farm tractors. On one of the very first shoots, I had to get in close for a detail shot, and the smell of the tractor somehow reminded me of my grandfather. Something sort of clicked.”

Today, Klancher still has a couple of tractors on the old Wisconsin homestead (“We do a little bit of hobby farming,“ he says), but you could hardly call Klancher a tractor collector, even though such people do exist. “It’s a surprisingly big community,” he says. “Naturally, it’s overwhelmingly rural, and to collect tractors, you have to have a lot of space. But I’ve met more than a half dozen collectors who have in excess of 300 machines, all kept indoors.”

This wide-front Farmall 404 from the 1960s is still used for planting. Collection Darrell Darst. Photo: Lee Klancher.

Like Klancher, these collectors almost always grew up on a farm. “If you think about a farmer, he has a unique relationship with his tractor. During the harvest, he’s going to spend 14 or 15 hours a day with this machine. It’s feeding his family, providing him with a livelihood. So I think for lots of farmers and their kids, the connection to tractors is really intense. You can still pick up a nice, old tractor for anywhere from $2,000 to $5,000, and they’re easy to restore. It’s not like restoring a car, which can be exacting. Anyone can do it. It’s a fairly economical hobby.”

Still, as in all things, being in the right place at the right time doesn’t hurt, as Jerry Mez of Avoca, Iowa, knows. His father, Max, got into the farm-implement business in 1943. Before he and his wife, Joyce, sold their Case IH dealerships in 2008, Jerry had collected hundreds of old tractors.

“Starting in the 1960s, he would take older tractors as trade-ins,” says Klancher, “so he was getting all this great stuff from the 1940s. In winter, when there wasn’t a lot going on and he didn’t want to let his staff go, he had them fix up the old tractors. He now has a museum called Farmall-Land USA with several hundred absolutely immaculate tractors in a heated and air-conditioned space that’s as clean as my kitchen. Some of those tractors are worth hundreds of thousands of dollars now,” he adds, “not just five grand. That’ll be a nice thing to leave to his kids.”

In 1991, the 7140 Magnum set a world record when Edgar Heyl of Hale, Germany, plowed 173.11 acres in 24 hours. Photo: Mark Jenson.

As the name of his museum suggests, Mez only collects farm equipment manufactured by International Harvester Company, which, for most of the 20th century, was the biggest name in tractors. The company’s lineage goes back to Cyrus McCormick, who may or may not have invented the first horse-drawn mechanical reaper in the 1830s. “It’s a dubious claim,” says Klancher, “but that’s true of pretty much any invention. Most innovation is done by some crazy guy somewhere, and then somebody else makes it all work and ends up in the history books.”

Though the McCormick Harvesting Machine Company of Chicago had been around since 1847, International Harvester Company’s march to farm-equipment supremacy began in 1902, when Wall Street financier J.P. Morgan brought the McCormick Harvesting Machine Company and its fiercest competitor, the Deering Harvester Company, together in a merger to create what would become International Harvester Company. “IHC controlled 85 percent of the farm market,” says Klancher of the newly formed agricultural colossus at the beginning of the 20th century. “They owned their own power plants, steel mills, railways; they even manufactured their own twine. Some of the members of the McCormick family married into the Rockefeller family. It was just a huge business. In fact, IHC was so big, it lost an anti-trust suit in 1917.”

The IH 660 was a favorite of wheat farmers in the early 1960s. Collection: Huber Brothers. Photo: Lee Klancher.

In the first half of the 20th century, about the only company to give IHC a run for its money was Ford, whose Fordson Model F of 1916 beat the IHC Moguls and Titans of the day on price, if not quality. “The Fords loved to poke sticks in the eyes of the McCormicks because Henry Ford’s little tractors were cheap. The first ones were not very good machines, but they were inexpensive and effective. The later Ford N-Series tractors made in 1939 were actually pretty good machines compared to the IHC stuff, which were big, clumsy, and expensive.” IHC corrected that, though, the very same year when it hired superstar industrial designer Raymond Loewy to redesign its profitable, but woefully out-of-date, Farmall line. The Letter Series tractors that followed (Farmall model names included the A, H, and M) went on to become the bestselling tractors ever.

“I’ve met more than a half dozen collectors who have in excess of 300 machines.”

Despite the popularity of Loewy’s redesigned Farmalls, by 1958, when “Red Tractors” picks up the company’s story, IHC was heavily in debt and struggling with the effects of union strikes. By 1963, despite having a record year, IHC was forced to watch competitor John Deere eclipse the company in terms of sales and profits, thanks in part to the growing popularity of a new crop of 100-plus horsepower Deere tractors. It would take more than 20 years for Harvester to finally regain its footing, when, in 1985, it merged with yet another competitor, J.I. Case, to create Case IH (Case got prominence of position in the new brand, but Case IH tractors continued to be IH red rather than Case orange). “That’s when the company was reborn and started its comeback,” says Klancher.

The 40 and 60 series tractors were introduced at the Hinsdale Farm in July, 1958. Photo: Wisconsin Historical Society.

The company’s products of the 1960s and ’70s illustrate how difficult it was to be in the farm-equipment business in the second half of the 20th century. “It’s massively expensive to create a farm tractor, more so even than an automobile because the machine has to last longer. The model cycles are also longer, the production units are lower, and the durability thresholds they have to achieve are unbelievable. The testing required for a piece of farm equipment is absolutely crazy.”

That’s why the Farm Equipment Research and Engineering Center (FEREC), established by IHC in the late 1950s in the Chicago suburb of Hinsdale, Illinois, on a 414-acre farm the company had owned since 1917, figures so prominently in “Red Tractors.” At the time, says Klancher, Harvester had “multiple locations throughout the United States. FEREC brought all the company’s engineers together in one facility. They had a cold room where they could vary the temperature, from something like 40 below zero to about 130 degrees above. They had indoor test tracks where they could run tractors continuously and test them year round. And they had sound rooms, which helped cab technology progress tremendously from the ’60s to the ’80s.”

In 1976, the red on International Harvester tractors got redder, and the brand and model number was set off in a black racing stripe. Collection: John Olson. Photo: Lee Klancher.

That last item might not sound like such a big deal, but when you consider how much time a farmer spends in his tractor, it is. Klancher has seen the evolution firsthand. “When I was first taking photos and getting into the old cabs, I often thought I was going to fall and break my camera. The approaches were really steep and narrow, and the doors were hard to get through. But when you get into a new Magnum, it’s like walking up a staircase into a living room. The sightlines are wonderful, pretty much all glass, so you can see the front wheels on the ground. In the old, early cabs, you couldn’t see anything, there was no room, and forget about AC.”

Beyond better creature comforts for operators, FEREC also improved tractor transmissions, the performance of which can be central to a farmer’s productivity. “I would say the biggest innovation of those years was the Axial-Flow Combine in 1977,” Klancher says, “but on tractors it would be the power-shift transmission, first introduced in 1969. Everyone understood that engaging a clutch, shifting, and then not being able to perfectly match your speed to your load was a problem. Power-shift transmissions allowed you to vary your speed infinitely rather than from gear to gear, but they were very expensive to develop. The technology was all there; the problem was the dollars to implement it. IH knew they needed this on-the-fly, synchronized transmission in the 1960s, but they didn’t get it right until 1979.”

Hidden within this 1966 vintage two-row picker is a Farmall 706 tractor. Collection: Bill Dahlenburg. Photo: Lee Klancher.

Sometimes, as in the case of power-shift transmissions, improvements were incremental, but other times testing at FEREC revealed potentially catastrophic flaws. “In the early 1980s, IH came out with its 50 series tractors. When that series was tested, they put the tractor on the test track and ran it day and night, until things broke.” Which they did. Specifically, it was discovered that the synchronizers designed to smooth shifting between the transmission’s 18 forward speeds (plus six reverse) were wearing out after a mere 50 hours of use. “I believe it was a $4-million fix,” says Klancher. “And this was just a few months before the tractor was supposed to be on the market.”

FEREC engineers also beefed up farm-equipment hydraulics, a technology that had only been around in the agriculture industry since the 1950s. “That progressed rapidly,” Klancher says. And it had to, because as the decades passed, farmers were doing more and more with less and less equipment. There were also fewer farmers. “The farmers were just screaming for more horsepower, heavier-duty hydraulic systems, and more powerful and faster PTOs.”

The 1976 tempera concept drawing for the 30 and 50 Series tractors by longtime IH designer Gregg Montgomery gave the machines a “Jetsons” look. Photo: Gregg Montgomery Collection.

That’s “power takeoff,” for those of you who, like me, didn’t grow up around tractors. “If you look at the back of a tractor,” Klancher says, “above the hitch, you’ll see a little pinion-gear pin sticking out. It spins so you can power implements like hay balers. To hook up your hay baler, you slide a shaft at the end of tractor-end of the baler over that pin, which allows you to engage and disengage that PTO. That’s how you power the implement. Since many of these farmers were going from farming 40 or 100 acres to farming thousands of acres, they needed tractors and implements that would cover a lot more ground. That meant everything had to be more powerful.”

The new machines also had to look up-to-date. “The first 50 series drawing done by Gregg Montgomery, the industrial designer who has designed all the IHs from about 1970 to today, is real Jetsons-y. It’s got a pointed nose and looks like a spaceship.” Unfortunately, access to the engine was limited to panels on the top and sides. “The enclosure for the engine was horrible. It looked great, but it was really difficult to work on. To this day, mechanics complain about it.”

(All photos from “Red Tractors: 1958-2013,” which is available from Octane Press.)

Our Dad, the Water Witch of Wyoming

Our Dad, the Water Witch of Wyoming

Frazier Dailey Makes the Case for Antique Tractors

Frazier Dailey Makes the Case for Antique Tractors Our Dad, the Water Witch of Wyoming

Our Dad, the Water Witch of Wyoming Barbed Wire, From Cowboy Scourge to Prized Relic of the Old West

Barbed Wire, From Cowboy Scourge to Prized Relic of the Old West Farmall TractorsUnder the leadership of Cyrus McCormick and Charles Deering, the Internatio…

Farmall TractorsUnder the leadership of Cyrus McCormick and Charles Deering, the Internatio… TractorsThe first tractors in the United States were introduced in the middle of th…

TractorsThe first tractors in the United States were introduced in the middle of th… Mari Tepper: Laying it on the Line

Mari Tepper: Laying it on the Line Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry

Nice Ice: Valerie Hammond on the Genteel Charm of Vintage Canadian Costume Jewelry How Jim Heimann Got Crazy for California Architecture

How Jim Heimann Got Crazy for California Architecture Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of

Modernist Man: Jock Peters May Be the Most Influential Architect You've Never Heard Of Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick?

Meet Cute: Were Kokeshi Dolls the Models for Hello Kitty, Pokemon, and Be@rbrick? When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll

When the King of Comedy Posters Set His Surreal Sights on the World of Rock 'n' Roll How One Artist Makes New Art From Old Coloring Books and Found Photos

How One Artist Makes New Art From Old Coloring Books and Found Photos Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures

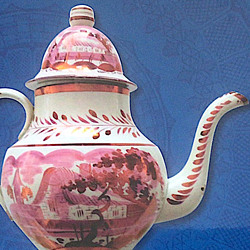

Say Cheese! How Bad Photography Has Changed Our Definition of Good Pictures Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History

Middle Earthenware: One Family's Quest to Reclaim Its Place in British Pottery History Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Fancy Fowl: How an Evil Sea Captain and a Beloved Queen Made the World Crave KFC

Nice cap on IH History.

I recently ran across you article, Rise of the Machines ; Tractors and the End of Rural America. I was interested to see several of my designs included in this article such as the Black Stripe 66 series tractor, the first Case International Magnum tractor, the Magnum tractor interior design, and a concept rendering that was part of development process for a new generation of tractors code named TR4 series. The only one of these designs you credited to me or Montgomery Design International was the concept rendering which you suggest was actually a production version of an IH tractor which it definitely was not. The eventual outcome of this project was the IH 50 Series and 30 Series tractors which at that time I had design responsibility for as Manager of IH Industrial Design. You suggest that the enclosed hood was a result of a desire to make it look like a “spaceship” which is totally incorrect. Firstly, the “Jetsons-y” spaceship comment is rather insulting, and as stated above, that particular design was never manufactured so all of the supposed service issues you mention are totally irrelevant with regard to this design. If you meant to criticize the hood design of the IH50 series tractor, you might want to do a bit more homework before you begin publishing misrepresentations of the facts. The enclosed hood was a feature of a revolutionary forward air flow system developed by IH engineers not IH designers. Also with a little study you would have found that those panels had all daily service items routed to them for easy access, and the enclosed hood provided the quietest tractor on the market, preceding todays noise requirements by 20 years. The 50 series tractor was no more difficult to service than a comparable John Deere or any other tractor of that era, since they all required panels to be removed for major service work. I would suggest that before you publish a critique of a person’s or company’s work, that you either interview the person or company in question, or at least do the aforementioned homework.

I would appreciate it if at some point you could publish some sort of clarification regarding these items, since your article paints a rather frivolous picture regarding serviceability, when nothing could be further from the truth.

Which one has the fan shaft running directly through the radiator just so the fan blade can be positioned on the front side?

Well, it’s what you should know, now a days it’s John Deere Green. For the reason of sentimentality I am still intriqued by the 86 series IH. Gotta give ’em respect, yessir. Mighty fine tractors accompanied by a very loyal following from back in the day.

The 50 series is a great tractor if the 1980’s would have been better for the ag industry deere would have had there hands full with what IH had coming!! And Gregg Montgomery did a wonderful job styling the 50 series and 2+2’s!! Thanks Gregg !

My new book is due June 2019

THE INTERNATIONAL HARVESTER COMPANY; A HISTORY OF THE FOUNDING FAMILIES AND THEIR MACHINES.

You guys talk about IH and J Deere like there weren’t any other tractors out there! I got news for you my granddad’s Massey-Harris Pony would work donuts around your crap anyday. The guy that owned the farm next to ours had an international 50 series and an old case grey. He ended up hiring my granddad and the pony to finish harvest season 1 year cuz both his tractors broke down. After we got done finishing his harvest season we turned around and finished ours with the pony! Later on we picked up a Colt and grandad and I laid into restoring it. We got it totally rebuilt and everything working on it when we ran across another Colt that needed the PTO rebuilt. We got it for $300 fixed the PTO then sold it to the neighbor for $1500. He got rid of his international & Case. And in 1992 when my grandad died that old neighbor was still doing all his farmwork with that Massey-Harris Colt we sold him. We humorously splashed red and green paint on our drive tires just so when people would ask we said its left over from the other tractors our pony ate for lunch!!